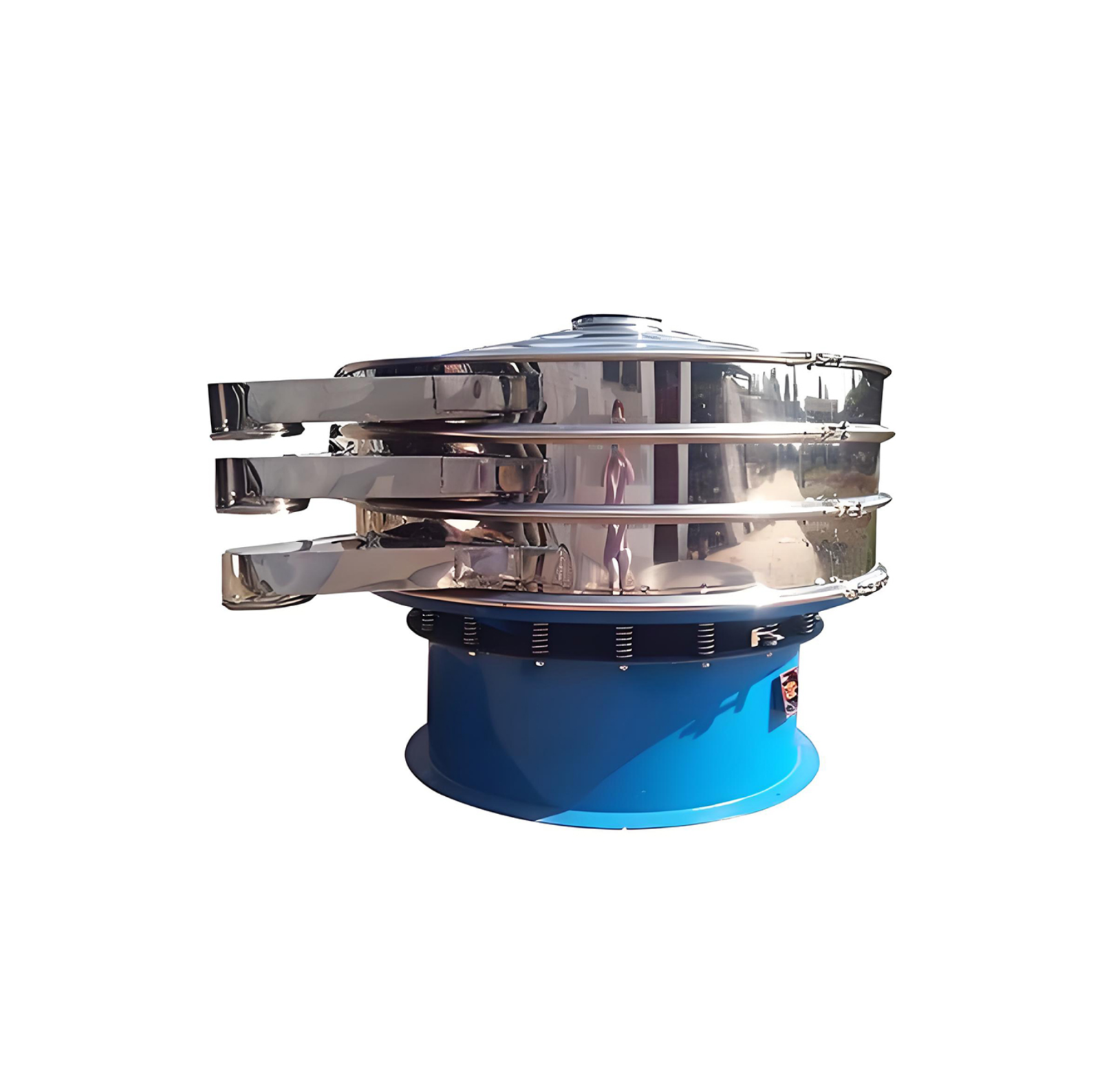

Product Details

Explore our advanced rotary vibrating screen, engineered for superior industrial powder separation efficiency. It excels in achieving screening accuracy of up to 500 mesh, catering to different operational needs.

1. Compact and lightweight design facilitates easy mobility, with the discharge port direction adjustable as needed; both coarse and fine materials are automatically expelled, allowing for manual or automated operation. 2. Exceptional screening accuracy and efficiency make it suitable for processing any powder, granule, or viscous material. 3. The screen remains unclogged, preventing powder dispersion, achieves screenings of up to 500 mesh (28 microns), and filtration levels as fine as 5 microns. 4. Innovative mesh configuration (mother-child type) prolongs screen lifespan; screen replacement is quick and straightforward, taking only 3-5 minutes, and ensures easy cleanup. 5. Operating without mechanical parts results in minimal maintenance; it can function effectively in both single and multi-layer setups, with all material-contact parts made of stainless steel (except for medical applications).

The rotary vibrating screen is versatile and designed to meet diverse screening requirements, including particle size classification, powder separation, and liquid filtration. It excels in processing both powdery and viscous materials, effectively eliminating impurities and contaminants.

- In the chemical industry, rotary vibrating screens play a crucial role in screening raw materials such as resins, coatings, and other industrial chemicals, as well as in processes like crystallization, milling, and filtration.

- Within the food industry, where product quality and hygiene are paramount, the rotary vibrating screen efficiently screens food ingredients like flour, sugar, salt, and milk powder.

- In the pharmaceutical sector, which demands strict adherence to product quality and safety standards, the rotary vibrating screen is adept at screening both Chinese and Western medicine powders while complying with GMP regulations.

- For the mining industry, it effectively screens raw materials including mineral powders and ores, ensuring optimal screening performance.

- Additionally, this innovative screening solution is widely employed across various other sectors, such as electricity, steel production, papermaking, as well as in waste disposal and wastewater treatment.